QATAR: +974 7745 4461 | sales@aageinternational.com

BAHRAIN: +973 3204 1771 | sm@aageinternational.com

Battery Monitoring System

Advanced Battery Monitoring Solutions for your Critical Applications

PowerShield has considerable experience in designing, developing and manufacturing battery monitoring equipment and systems for many applications and industries. PowerShieldgives organizations confidence their battery bank will always be available and get the best possible life out of their battery investment.

Established in 1996 and based in Auckland, New Zealand, PowerShield is independently owned and works with all the leading power conditioning and backup power companies. PowerShield is committed to continuous improvement, quality management and fulfilling obligations to the environment. PowerShield is certified to ISO9001 Quality standard, ISO14001 Environmental management standard and ISO45001 Health and Safety management system certification.

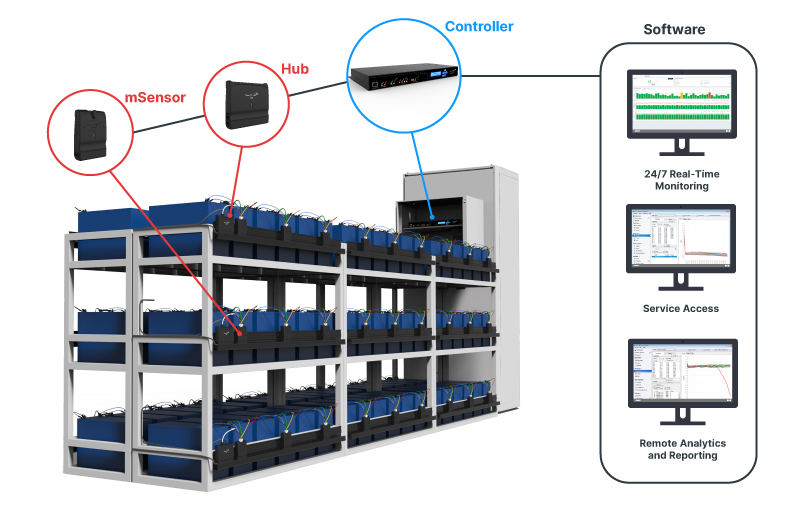

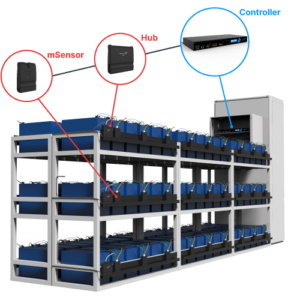

The PowerShield battery management system combines robust hardware devices for the reliable monitoring and collection of battery data with smart software dashboards. From data centers to critical infrastructure such as transportation, utilities, telecommunications and healthcare, these provide a real-time view of battery health and predictive analytics about future performance. All are backed by world-class technical expertise in battery management.

PowerSheild operates globally and has installed battery monitoring solutions with customers in over 50 countries around the world. International customers include Bank of America, Barclays, Bloomberg, BT, CenturyLink, Chevron, Equinix, Huawei, IBM, Intel, Microsoft, Morgan Stanley and NASA.

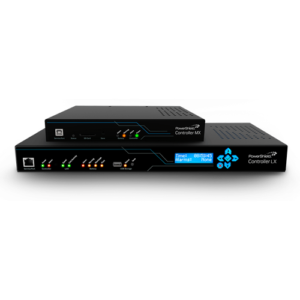

PowerShield Battery Monitoring System

How does the Reporting Service work?

- The PowerShield system monitors your standby batteries continuously measuring and storing data – for the lifetime of the batteries.

- At the end of each day the PowerShield system sends your battery data to our secured server and we replicate your database. We don’t access your network so the integrity of your system security is maintained.

- Every month we analyze and interpret your battery data and a PowerShield battery expert prepares a report on the overall condition of your batteries and recommends actions for you to take.

- The actions you take will correct any small problems before they escalate, meaning your batteries will be available when you need them.

- Your service partners or staff can act with confidence and apply themselves to other important tasks, instead of worrying about battery health.

The PowerShield Reporting Service is a great option if you don’t have the staff, expertise or resources to analyse all the information generated by the PowerShield Battery Monitoring System.

If you’d prefer to receive an independent or external view on your battery data – or simply get a second opinion – the PowerShield Reporting Service is a cost-effective way to receive expert analysis and interpretation of your battery data.

Every month we analyze and interpret your battery data

What does the report tell you?

Trend analysis will identify potential battery failures and help you to identify and manage battery end-of-life.

Depending on the configuration of your PowerShield Battery Management System the report will give you a visual summary for your batteries, highlighting the overall status and any exceptions in:

- Ambient temperature

- Float voltage

- String current

- Individual battery temperature

- Individual battery impedance (ohmic value)

- Individual battery voltage

All discharges are reported, issues recorded and recommended maintenance actions are listed.

Between reports the PowerShield Battery Management System will continue to notify you directly of any alarms where immediate onsite action is needed.

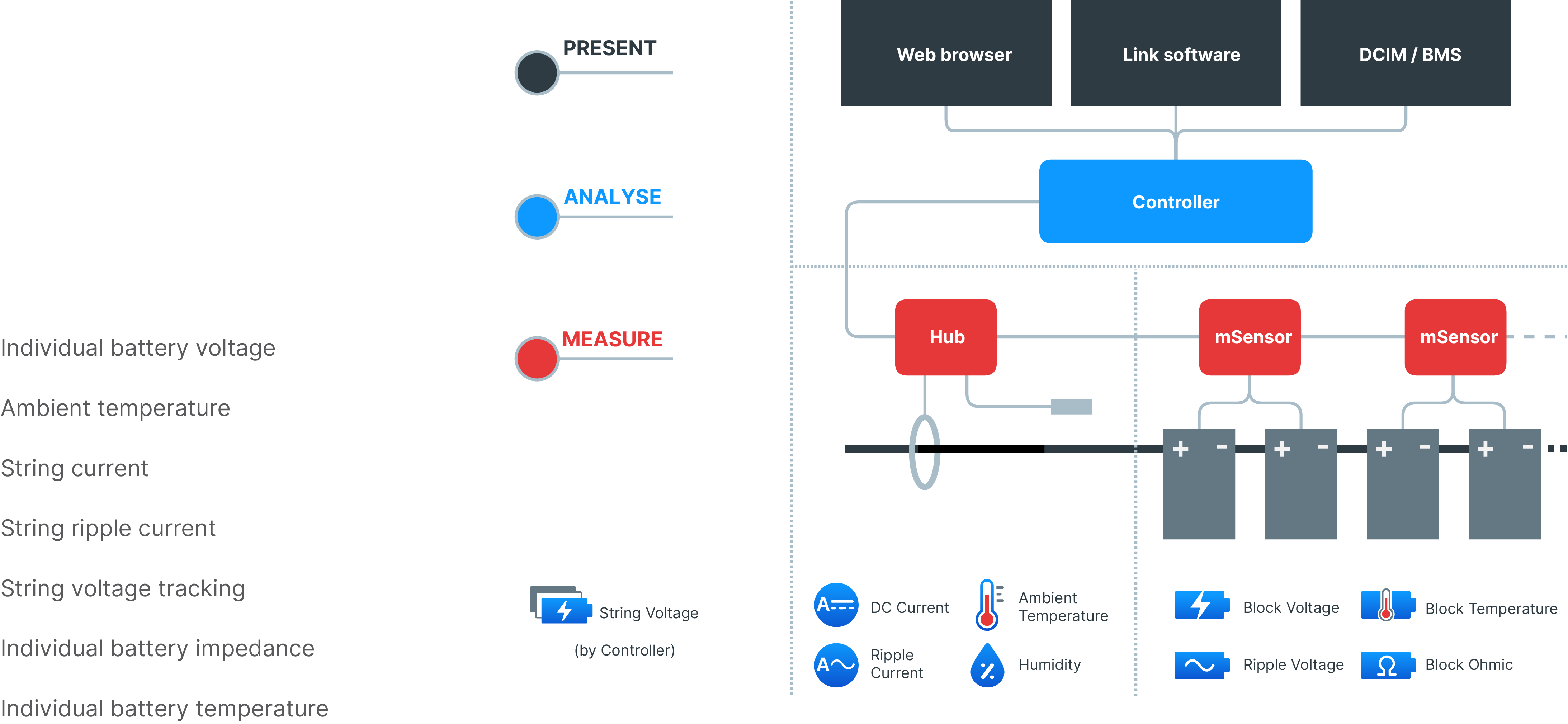

PowerShield measures a range of individual battery and string parameters

PowerShield systems provide permanent and continuous monitoring for stand-by battery installations. Individual battery and string parameters are measured against user-defined limits specific to battery state (float, idle, charge and discharge) supporting both float and intermittent charging regimes.

Individual Battery Voltage

Correct float voltage is critical for battery life. Incorrect charge voltages may result in loss of capacity, accelerated grid corrosion, excessive gassing and premature end of life. Voltage also identifies catastrophic failures, such as short circuit cells, and gives true visibility of performance under discharge.

Individual Battery Temperature

Measuring the temperature of each battery allows the early detection of thermal runaway. It pinpoints localized environmental problems through poor HVAC and can also highlight poor connections under discharge and excessive charger ripple. A common failure mode for Ni-Cds is separator failure which can be detected with temperature.

String Voltage

Tracking the string voltage confirms the charger is operating and the batteries are being charged at the correct voltage.

String Ripple Current

Detect excessive ripple current or unexpected changes over time.

Individual Battery Impedance (Ohmic Value)

The impedance of a battery will increase with age. High impedance results in a battery that cannot supply the required current – its key task. By trending impedance, you can accurately determine end-of-life. High impedance readings also highlight poor connections and open circuit batteries before failure.

Batteries can fail in a very short period (less than a week) so measuring impedance daily allows you to detect faulty batteries – without the need to discharge them.

Ambient Temperature

A battery’s life span is normally specified at 20 or 25 degrees Celsius. Temperatures outside of the specified range can significantly affect the battery’s corrosion rate, and therefore the life of the battery. An 8-10 degree temperature increase can decrease battery life by 50%.

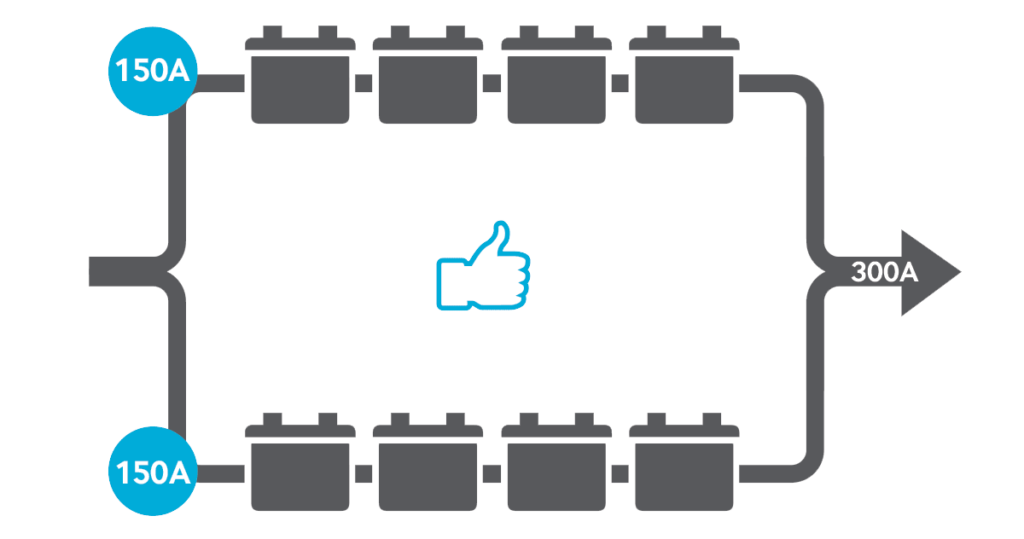

String Current

String current monitoring measures the energy delivered or accepted by each battery string. A UPS will only measure total current and cannot detect imbalances between strings. An imbalance highlights potential problems within a battery string.

String current measurement also allows the detection of incorrect battery charging and any significant earth leakage faults.

PowerShield’s System Integration

PowerShield battery management systems can be configured to operate as stand-alone systems or integrated with existing facility management systems or data center infrastructure management (DCIM) solutions such as Foreseer, Struxure Ware, Trellis, by Vertiv Critical Insight and Siemens BMS.

We offer a range of communications solutions to keep you informed about the health of your batteries.

- Ethernet – PowerShield Link battery management software brings your batteries to your desktop via the LAN. Email alerts are sent directly to your service team

- Modbus RTU, Modbus TCP, SNMP – Integrate PowerShield with your existing facility management systems allowing a single focus for control room personnel

- Dedicated RS232 Service Port for service teams

- 4 Configurable relay outputs for alarm notification

- Buzzer for on-site audible alerts

- 4 Configurable digital inputs – consolidate other device alarms through PowerShield.

Link Battery Management Software

Link battery management software is a window into the health and performance of your battery systems. It enables you to make informed decisions quickly and proactively. Bundled with your PowerShield8 system, the Link software application manages the Controller and records all battery readings in its database for viewing, trending and reporting.

Data is turned into actionable information in the form of alerts and dashboards. The link also sends key information to the control room and facility management systems. Available across sites and to multiple users, Link comes with no additional licensing or costs.

Contact Us

We are a strategically placed service provider and we can reach you quickly.