The secret to a battery’s long life lies in some basic do’s and don’ts that make things easier in case of an emergency. The clarity and the awareness that we impart to all our clients come directly from past real-life scenarios in battery rooms, hence it makes an effective impact on the protocols followed in battery maintenance. We have grouped some questions that we faced ourselves or from our clients in this industry. We have given the answers to ensure that the knowledge that we have shared here saves a lot of time and money.

The models, designs, and specifications of high-end industrial batteries are upgraded regularly. To keep up with the latest in technology we need to ensure that we are well informed on the pros and cons of these models. We have this FAQ section as a regularly updated one to give some answers to some intriguing questions that can help in purchase of PowerShield Battery Monitoring System or maintenance.

How does PowerShield help

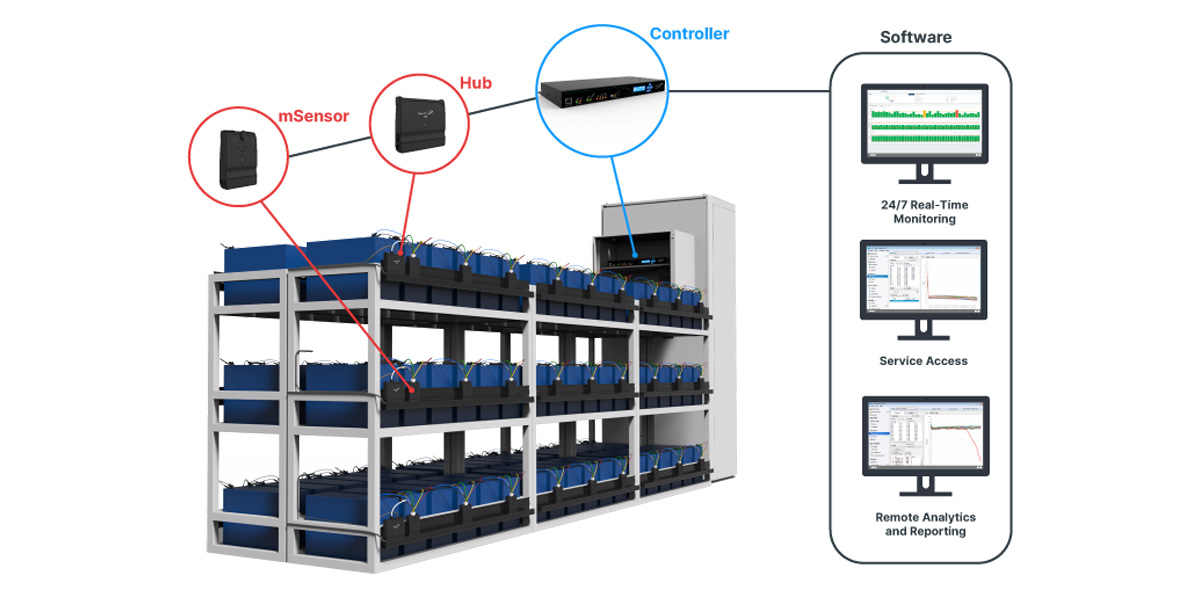

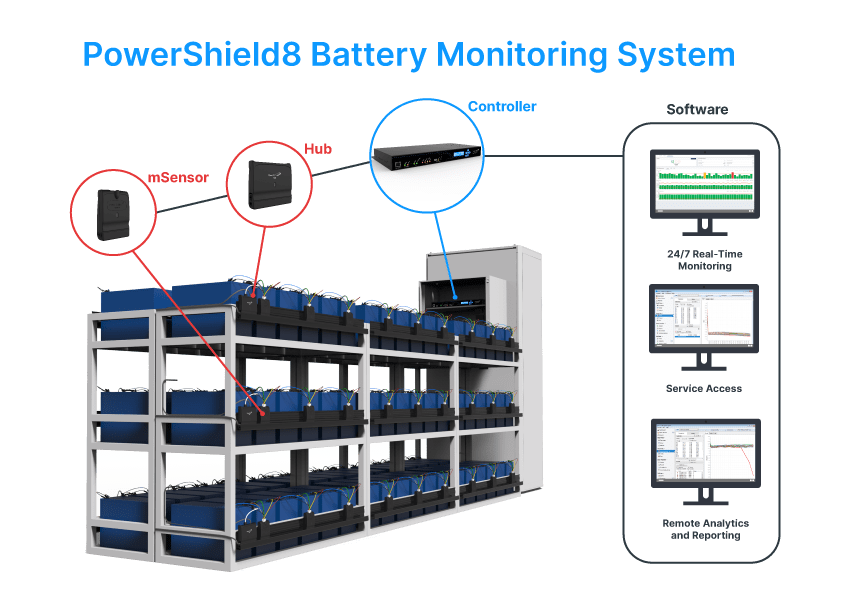

PowerShield uses a combination of sensors, data collection, and sending the data to the control center concerning the battery status daily. With this data, our clients are recommended the course of action to maintain their batteries in peak performance condition till the service life of the battery.

How is the data collected?

The sensors on the batteries record the peak performance trends, low and high voltages, battery temperature, and all other factors concerning the normal operation of a battery. The onboard systems attached to the batteries are integrated with software that collects these data in an organized fashion

Should someone note down these readings?

Not required. The process is fully automated and the data collected is transmitted to the control center through a separate network.

Is an In-house Engineer required?

No. Our control center will receive the data collected and analyze it. We send our recommendations to the concerned team with the remedial action.

How can I rely on your data?

We are certified with ISO9001, ISO45001, and ISO14001. We operate in more than 50 countries and we ensure that the entire data collection from the batteries operates in a separate network in all our client’s places.

What’s the overall process?

The sensors in batteries detect the pre-programmed values and send them to the controllers. The controllers in the battery room collect and store these data to be sent to the service team and the control room. Due action can be taken once the data is analyzed for any malfunction even in a single battery.

What application is used?

Powershield8 is a versatile application that can work in both online and offline modes. One license is enough for any number of devices. We have both LX and MX controllers for big and small facilities respectively.

Will I get alerts 24/7?

The kind of reporting structure requirements will be met as per the schedule and in case of an emergency, we are accessible at all times. You can link the application to your department and can get alerts as emails.

What is Link Software?

Link software integrates the user with the battery maintenance application which is a simple interface. Any number of users can access the data simultaneously and the options available in the dashboard will help you assess your battery condition.

Factors affecting the battery performance?

Temperature, both operational and environmental, over or under-charging, poor to nil maintenance, sub-standard quality of battery materials, poor ventilation, rough handling, and manufacturing defects can affect the performance of the batteries. These factors are to be analyzed as part of the maintenance schedule or apparently, they will fail during a power failure.

A Simple Tip to avoid a major catastrophe

Continuous data generation from PowerShield systems gives the general trends of the battery usage, the frequency of the peak and low power periods, and important alerts on the battery status so that we will not have any undue surprise during a power outage. An undetected battery failure will increase the load on the other batteries in its string and will gradually decrease the capacity of the batteries in that network.

What are the application areas of PowerShield Systems?

Data centers, labs, telecommunication systems, water services, healthcare, hospitals, etc use our reliable OEM to get 100% battery status report at all times.

Is it worth the money?

We give assurance that the reports will have a timely response attached with the recommended course of action concerning the battery’s status. A single battery unit affects the efficiency of all the batteries in the loop and if not corrected in time will end up in replacing all the batteries before their service life.

How versatile is the software Power Shield8

The capabilities of our software are as follows:

- Identifying even a single battery in an assortment of batteries in the network

- Works for any model and type

- Real-time and archived data access

- Alarm settings for preset values, even thermal runaway can be detected

- Designed as per IEEE/IEC standards

What are the components of Power Shield8?

Our controllers, sensors, link battery management software, and a hub as required.

What values are reported?

The temperature of the battery, impedance, string current, and voltage.

Will there be complexity involved in the operation?

The installation, configuration, and operations will be smooth and tidy without occupying much space. We can do it ourselves or with any accredited installer depending on your location.

How is it integrated?

Either as a stand-alone system or a part of your FMS or DCIM.

What is the DCIM software compatible with?

Foreseer, StruxureWare, Trellis, Vertiv Critical Insight, and Siemens BMS.

What are all the options available for system Integration

Several options are available like Ethernet connected to your LAN, Modbus RTU, Modbus TCP, SNMP connected to your facility management system, and an RS232 port.

I need a customized solution, is it possible?

We have a dedicated team of determined staff for innovation and improvements in the current design and we can accommodate any customization and tailor-made requirement needs.

What’s the overall Schema

Is it suitable for all types of batteries

Yes, it is suitable for VRLA or VLA (wet cells), lead acid or Ni-Cd.

What is the country of origin of PowerShield

It’s manufactured in Auckland, New Zealand

Who is the Authorised distributor in the Middle East

AAGE International Trading & Contracting is the authorized distributor for the Middle East

Comments are closed.